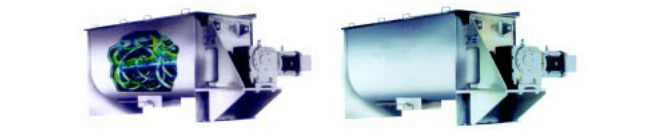

RH ribbon-type mixer

Applications

--Agricultural field: For mixing of pesticide, chemical fertilizer, breading material and additives.

--Foodstuff industry: For mixing of baby food, keke, animal breading material, salt wheat flour and milk powder etc.

--Material draying: To dry powder material.

--Chemical industry: For mixing of grinding material, catalytic agent, ceramics, dying material, plastics, resin, cosmetics, detergent paint etc.

Performance features

- The mixer suits to the mixing of solid-solid powder and solid-liquid material

--The mixer suits to normal pressure operation environment. A direct driving device can bring the equipment to rotate. A special designed pitch controllable coupling can start the machine with full load that prevent any risk of overload operation.

--According to the requirement of customer, the mixer can be designed for vacuum type with cooling and sleeve devices.

--Fast mixing speed. The mixer can complete material mixing in 10 minutes.

-- Manual, electric and hydraulic modes optional for material discharge.

Working principle

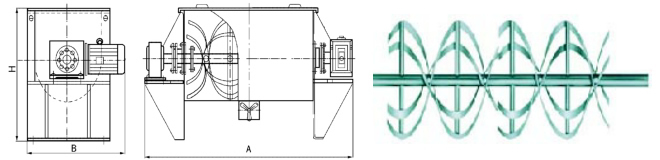

The structure of RH ribbon mixer is shown in the figure below. It consists of a U-type cylinder (driving mechanics), cover, supporting frame and discharge mechanics. The motor through speed reducer move the ribbon stirrer to make the material movement up and down and form internal and external exchange so as to realize uniform mixing. There are three types of stirring designs—continuous ribbon, cutting ribbon and paddle. Selection of stirring types depends on the condition of discharge from center and the bottom.

Type |

Processing capacity

m3 |

Power

KW |

Rotational speed

rpm |

Size(mm) |

Length |

Width |

height |

RH-1 |

0.028 |

1.1 |

80 |

1050 |

600 |

700 |

RH-5 |

0.142 |

2.2 |

60 |

1700 |

1000 |

1030 |

RH-10 |

0.283 |

5.5 |

60 |

2200 |

1020 |

1000 |

RH-18 |

0.5 |

7.5 |

55 |

2500 |

1100 |

1130 |

RH-25 |

0.7 |

11 |

45 |

2550 |

1250 |

1200 |

RH-36 |

1.0 |

15 |

45 |

3010 |

1810 |

1200 |

RH-52 |

1.5 |

18.5 |

40 |

3100 |

1950 |

1350 |

RH-71 |

2.0 |

18.5 |

35 |

3800 |

2180 |

2130 |

RH-100 |

2.8 |

22 |

25 |

4210 |

2300 |

2180 |

RH-180 |

5.1 |

37 |

20 |

4720 |

2920 |

2240 |

RH-270 |

7.6 |

45 |

20 |

5000 |

3400 |

2350 |

RH-515 |

14.6 |

90 |

15 |

6450 |

4000 |

3200 |

Notes:

1 The electric power changes with material property. Power figure in the table is calculated from material with gravity of 512kg/m3 without flowing. The max weight of the feeding material to the equipment is (kg) =working capacity (m3) x 512kg/m3.

2. Standard mixer without sleeve and liquid spreader.

|

|