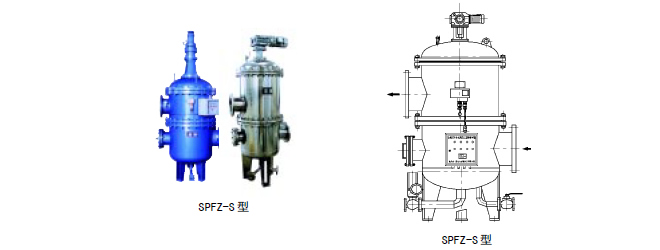

Sucking-type auto-washing filter (SPFZ-S type)Features◆ SPFZ-S type filter adopts NRV speed reducer. The shell is aluminum alloy cast structure in characteristic of good radiation, low noise and lightweight and heavy pressure bearing capability.

◆The sealing device of SPFZ-S type filter adopts double-end sealed structure with enhanced tetrafluoroethylene in accordance with CV62.1-85 standard. The filter features reliable

sealing, long lifetime and heavy pressure bearing capability.

◆SPFZ-S type filter is designed with discharge valve on the top which features compact structure and sensitive opening and closing function.

◆The differential controller system adopts D520/7DD switch to adjust differential controller, thus guaranteeing correct signal feedback and its sensitivity.

◆SPFZ-S type filter adopts multiple filter element structure, featuring large filtering area, low-pressure reduction and high backwashing efficiency.

◆The cartridge plate is made of stainless steel which implements filtration process at the working interface of backwashing sucking disc.

◆The backwashing sucking disc adopts reinforced tetrafluoroethylene structure and backwashing auto-handling mechanism to guarantee longtime sealing between the sucking disc and the cartridge, which enhances the backwashing effect.

◆The electrical control system adopts PLC programmable controller. The washing mode adopts parallel mode of differential control, time control and manual control. Time fixing and location washing mode can obtain lower flow rate and thorough backwashing.

◆No flow failure during backwashing. Applications● Industrial sewage Applications● Industrial sewage

● Filtration of circular water

● Regeneration of emulsion

● Filtration of waste grease

● Continuous cast water supply system of Metallurgical industry

● High pressure water used for steel rolling in furnace systemWorking principleThe SPFZ-S type filter consists of a shell body, multiple filter elements, a backwashing mechanism, an electric control system, a power unit, an electric sewage valve and a differential control system. In the shell body, the cartridge card divides the internal cavity into up cavity and down cavity. In the up cavity, there are multiple filter elements, which reduce the volume of the filter body. In the down cavity, there is a backwash-sucking disc. During operation, the dirty liquid enters the filter through tin inlet and then into the inner cavity of filter elements through holes on the cartridge. Particles bigger than the hole will be cut off. The purified liquids will flow out from the up cavity.

When dusts are accumulated at the cartridge surface and the pressure difference in the inlet and outlet locations become bigger than the predefined value or the timing device reaches predefined time interval, the electric control system will send a signal to drive the backwashing mechanism. When the backwashing sucking disc opening become opposite to the cartridge inlet, the sewage valve will be open, the filter system begins sewage discharge. A negative pressure region will appear in the sucking disc and the inner side of cartridge. As a result, it forces part circulation liquid into the inner side of cartridge. Dusts remain on the inner side of cartridge will into the sewage discharge chamber with liquid flow and flow out from the sewage discharge valve. The specially designed filter cartridge presents good injecting effects to wash out any kinds of dust. When pressure difference in the inlet and outlet locations become normal or the timer’s setting interval ends, the motor will stop running, the sewage discharge valve will close. During whole process, now stream fails. The backwashing operation not only features less water consumption but also implements continuous and automatic operation. Technical parameters

| Maximum flow rate |

3000m3/h |

According to the filtering precision and impurity content to this company, my company to provide the most appropriate machine |

| Minimum working pressure |

0.4Mpa(g) |

|

| Minimum working pressure |

1.6Mpa(g) |

special on customer request |

| Diameter of inlet and outlet |

DN50 ~ DN700 |

flange standard HG20592-97, special on customer request |

| Minimum working temperature |

80℃ |

special on customer request |

| Filtering accuracy |

25~3000μm |

|

| Screen material |

provide 304,316,316Lstainless steel on requests |

|

| Equipment material |

Provide Carbon steel or 304,316,316L stainless steel on requests |

|

| Motor power |

0.37~0.75KW |

|

| Power voltage |

380V, 50Hz, 3-phase |

|

| Backwashing flow rate |

less than 1~2% of overall flow |

|

| Backwashing time |

60” |

|

| Backwashing pressure difference |

0.5kg/cm2 |

Set by process demand | Notes:Because the features of material are different, the company can provide design of particular filters requested by the customers. The customer should detail related parameters such as flow rate (m3/h), filtering precision (μm), pressure (Mpa), density (kg/m3), viscosity ( CP ). Please contact the company for erecting drawings. Standard level of filtration Standard level of filtration

|

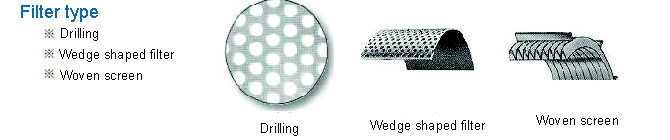

Filter type |

Drilling |

Wedge shaped filter |

Woven screen |

|

µm |

3500 |

2500 |

1500 |

800 |

500 |

300 |

200 |

200 |

130 |

100 |

80 |

50 |

25 |

|

mm |

3.5 |

2.5 |

1.5 |

0.8 |

0.5 |

0.3 |

0.2 |

0.2 |

0.13 |

0.1 |

0.08 |

0.05 |

0.02 |

|

mesh |

4 |

6 |

10 |

20 |

30 |

50 |

75 |

75 |

120 |

155 |

200 |

300 |

450 |

|

|