SLH-type high-efficiency heat exchanger

Product descriptionGeneral tube still heat exchanger featuring simple structure, low-cost and wide common utilization has been widely used. But due to bigger uneven distribution of sectional temperature in the tubes to high-viscosity medium, the heat exchange operation and heat-exchanging efficiency becomes lower so as leading quality degradation problems.

Aiming at this problem, our company through long term study of related technologies and joint research with other institutes has developed SLH-type high-efficiency heat exchanger.

SLH-type high-efficiency heat exchanger adopts static hybrid elements with heat conductive coefficient 3~6 times higher than that of common heat exchanger. The static hybrid elements show superiority in heat conduction that is identified by many professional persons, saying that the success of developing SLH-type high-efficiency heat exchanger proves the similarity theory of heat transfer and medium transfer.

Performance features

In addition to the superiorities of general tube still heat exchanger, SLH-type high-efficiency heat exchanger has additional features as:

1. Higher heat transfer efficiency especially to high viscosity medium

2. Without non-uniform distribution of sectional temperature of material in the pipe;

3.The piping pass has a function of auto-cleaning;

4.Similar heat transfer effect can be obtained by means of reducing the heat-transfer temperature deviation, reducing the entropy loss and raising the utilization of heat energy.

5. Similar heat transfer effect can be obtained by means of reducing the heat-transfer area and reducing land occupation by the equipment.

Application scope

SLH-type high-efficiency heat exchanger is suitable to heat transfer operation to high viscosity material with viscosity scope of 50~500000cp. It is widely used in petrochemical industry, foodstuff industry and synthetic fiber industry, such as PBT, PET Polyacrylonitrile fiber Polyethylene terephthalate etc., (Contact us for detailed design and type selection).

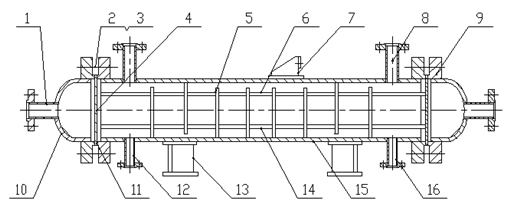

Structure

1.Pipe shell 2. Bolt 3. Nut 4. Pipe sheet 5. Baffle 6. Heat transfer tube 7. Ear support 8. Exhaust outlet 9. Flange 10. Head 11. Sheet 12. Drainage outlet13. Support 14. Pull-rod 15.Cylinder 16. Shell connecting pipe

Notes:

1. This series belongs to fixed pipe plate type

2. The heat transfer tubes are arranged in triangular mode according to related standard;

3. The baffle is arch type with opening in up and down position or in right and left position;

4. The shell inlet is designed without baffle plates. If they are wanted, make it clear during ordering.

5. The erection form can be in vertical arrangement or horizontal arrangement;

6. The tubes and pipe plates are connected by welding operation;

Flanges used for this series equipment are concave-convex flange. The piping flanges are selected according to process calculation or the request of customer.

Technical Parameters

|

Type |

Nominal diameter DN(mm) |

Dimension of heat transfer tubes |

Pipe no. |

Heat exchange aream2 nominal value/calculated value |

Shell channel area m2 |

|

Pipe length(mm) |

|

750 |

1000 |

1500 |

|

SLH150 |

159X4.5 |

ф19 |

15 |

0.5/0.62 |

1/0.85 |

1.5/1.29 |

0.0022 |

|

ф25 |

10 |

0.5/0.55 |

0.8/0.75 |

1/1.14 |

0.0027 |

|

SLH200 |

219X6 |

ф19 |

36 |

1.5/1.50 |

2/2.04 |

3.0/3.11 |

0.0053 |

|

ф25 |

22 |

1/1.21 |

1.5/1.64 |

2.5/2.50 |

0.0060 |

|

SLH250 |

273X6 |

ф19 |

69 |

3/2.88 |

4/3.91 |

6/5.97 |

0.0102 |

|

ф25 |

40 |

2/2.20 |

3/2.98 |

5/4.55 |

0.0110 |

|

SLH300 |

325X8 |

ф19 |

106 |

/ |

6/6.00 |

9/9.17 |

0.0157 |

|

ф25 |

62 |

5/4.64 |

7/7.06 |

0.0170 |

|

SLH400 |

400X10 |

ф19 |

195 |

/ |

11/11.05 |

17/16.86 |

0.0290 |

|

ф25 |

110 |

8/8.20 |

13/12.52 |

0.0301 |

Notes:

(1) Pressure 0.6, 1.0, 1.6 and 2.5 Mpa, four types (Vacuum according to 0.6 MPa );

(2) Temperature: According to material permitted temperature. The design temperature of this series is 200 oC. Temperature increase or pressure reduction operation can be applied.

Material: 16MnR; 1Cr18Ni9Ti; Q235-A; 0Cr17Ni12Mo2Ti.

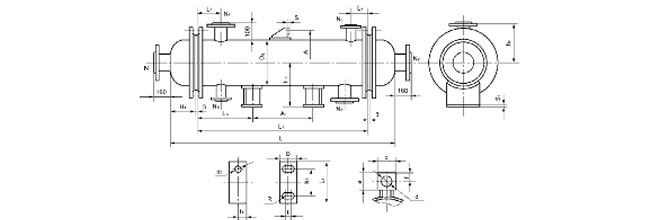

Erection Size

SLH150

SLH150

|

Parameter

mm |

Pressure MPa |

|

0.6 |

1.0 |

1.6 |

2.5 |

|

Pipe length |

|

750 |

1000 |

1500 |

750 |

1000 |

1500 |

750 |

1000 |

1500 |

750 |

1000 |

1500 |

|

Connection pipe |

|

L0=100 h0=239.5 |

|

Lf |

28 |

32 |

36 |

38 |

|

DN |

N1-2=50 N3-4=40 N5-6=20 |

|

Horizontal support |

A1 |

242 |

492 |

992 |

242 |

492 |

992 |

242 |

492 |

992 |

242 |

492 |

992 |

|

LA=250 H2=280 L2=170 K1=90 D1=20

F=60 B=140 R=10 t=20 S1=10 |

|

Vertical support |

A=442 d=24 f=30 S=6 c=100 a=60 A total of 2 |

|

H1 |

72 |

|

L1 |

742 |

992 |

1492 |

742 |

992 |

1492 |

742 |

992 |

1492 |

742 |

992 |

1492 |

|

L |

892 |

1142 |

1642 |

892 |

1142 |

1642 |

892 |

1142 |

1642 |

892 |

1142 |

1642 |

|

Weight(Kg) |

107 |

118 |

140 |

119 |

130 |

152 |

129 |

140 |

162 |

141 |

152 |

174 |

SLH200

Parameter

mm |

PressureMPa |

| 0.6 |

1.0 |

1.6 |

2.5 |

| Pipe length |

| 750 |

1000 |

1500 |

750 |

1000 |

1500 |

750 |

1000 |

1500 |

750 |

1000 |

1500 |

| Connection pipe |

|

L0=100 h0=269.5 |

| Lf |

32 |

34 |

40 |

42 |

| DN |

N1-2=50 40 N3-4=50 N5-6=20 |

| Horizontal support |

A1 |

242 |

492 |

992 |

242 |

492 |

992 |

242 |

492 |

992 |

242 |

492 |

992 |

| |

LA=250 H2=310 L2=215 K1=120 d1=20

F=60 B=140 R=10 t=20 s1=10 |

| Vertical support |

A=506 d=24 f=30 s=6 c=100 a=60 A total of 2 |

| H1 |

88 |

| L1 |

742 |

992 |

1492 |

742 |

992 |

1492 |

742 |

992 |

1492 |

742 |

992 |

1492 |

| L |

924 |

1174 |

1674 |

924 |

1174 |

1674 |

924 |

1174 |

1674 |

924 |

1174 |

1674 |

| Weight(kg) |

135 |

162 |

206 |

150 |

185 |

220 |

160 |

185 |

231 |

185 |

210 |

254 |

SLH250

Parameter

mm |

PressureMPa |

| 0.6 |

1.0 |

1.6 |

2.5 |

| Pipe length |

| 750 |

1000 |

1500 |

750 |

1000 |

1500 |

750 |

1000 |

1500 |

750 |

1000 |

1500 |

| Connection pipe |

|

L0=100 h0=269.5 |

| Lf |

30 |

|

32 |

38 |

| DN |

N1-2=80 N3-4=50 N5-6=20 |

| Horizontal support |

A1 |

242 |

492 |

992 |

242 |

492 |

992 |

242 |

492 |

992 |

242 |

492 |

992 |

| |

LA=250 H2=337 L2=265 K1=160 d1=20

f 1=60 B=140 R=10 t=20 s1=10 |

| Vertical support |

A=562 d=24 f=30 s=6 c=100 a=60 A total of 2 |

| H1 |

88 |

| L1 |

742 |

992 |

1492 |

742 |

992 |

1492 |

742 |

992 |

1492 |

742 |

992 |

1492 |

| L |

952 |

1202 |

1702 |

952 |

1202 |

1702 |

952 |

1202 |

1702 |

952 |

1202 |

1702 |

| Weight(kg) |

Ф25 |

203 |

233 |

293 |

225 |

255 |

316 |

250 |

280 |

341 |

275 |

304 |

306 |

| Ф19 |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

SLH300

Parameter

mm |

PressureMPa |

| 0.6 |

1.0 |

1.6 |

2.5 |

| Pipe length |

| 1000 |

1500 |

1000 |

1500 |

1000 |

1500 |

750 |

1000 |

1500 |

750 |

1000 |

1500 |

| Connection pipe |

|

L0=125 h0=322.5 |

| Lf |

32 |

36 |

40 |

44 |

| DN |

N1-2=100 N3-4=65 N5-6=25 |

| Horizontal support |

A1 |

392 |

892 |

392 |

242 |

892 |

392 |

892 |

392 |

892 |

| |

LA=300 H2=363 L2=310 K1=200 d1=20

F=60 B=140 R=10 t=2 s1=10 |

| Vertical support |

A=662 d=30 f=60 s=10 c=140 a=120 A total of 2 |

| H1 |

116 |

| L1 |

992 |

1492 |

992 |

1492 |

992 |

1492 |

992 |

1492 |

| L |

1230 |

416 |

1230 |

416 |

1230 |

416 |

1230 |

416 |

| Weight(kg) |

Ф25 |

324 |

416 |

348 |

440 |

367 |

459 |

424 |

516 |

| Ф19 |

— |

— |

— |

— |

— |

— |

— |

— |

SLH400

Parameter

mm |

PressureMPa |

| 0.6 |

1.0 |

1.6 |

2.5 |

| Pipe length |

| 1000 |

1500 |

1000 |

1500 |

1000 |

1500 |

1000 |

1500 |

Connection pipe |

L0 |

150 |

| h0 |

363 |

364 |

366 |

366 |

| L1 |

|

|

|

|

| DN |

N1-2=150 N3-4=100 N5-6=25 |

| Horizontal support |

A1 |

292 |

792 |

292 |

792 |

292 |

792 |

292 |

792 |

| H2 |

411 |

412 |

414 |

414 |

| |

LA=300 L2=410 K1=280 d1=20 f1=60

B=140 R=10 t=20 S1=10 |

| Vertical support |

A |

754 |

758 |

766 |

766 |

| |

f=60 S=10 c=140 a=120 A total of 2 |

| H1 |

116 |

| L1 |

992 |

1492 |

992 |

1492 |

992 |

1492 |

992 |

1492 |

| L |

1302 |

1802 |

1302 |

1802 |

1302 |

1802 |

1302 |

1802 |

| Weight(kg) |

ф25 |

492 |

617 |

515 |

640 |

592 |

715 |

627 |

752 |

| ф19 |

— |

— |

— |

— |

— |

— |

— |

— |

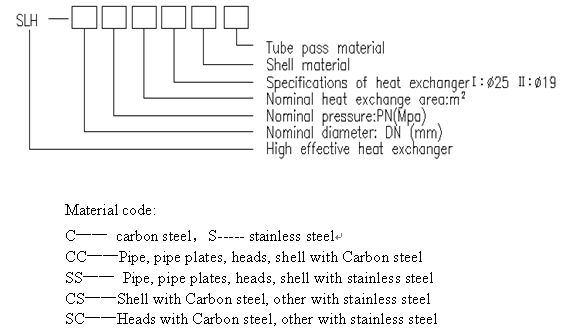

Denotation of product types

If nominal diameter is 300, nominal pressure is 1.0Mpa, heat exchange area is 9m2, the heat transfer tube is φ19 shell with carbon steel. The other heat exchanger is made with stainless steel. The model is shown as SLH300-1.0-9II-CS.

Application example

In a poly-condensation process to produce PBT in a factory with phototube heat exchanger with specification of 21m2, after using this high-efficient heat exchanger with heat exchange

area only 3.6m2, the parameter of energy saving and heat exchange efficiency become evident. The related material parameters are as follows:

1. Tube pass: PBT Pre-polymer, gravity 1.1t/m3, viscosity 1400cp, specific heat 0.65kcal/kg oC, thermo conductive coefficient 0.106kcal/m.h.oC, flow rate 15100kg/h, pressure 0.7Mpa, scaling coefficient 0.0002m2.hoC, temperature from 240 0C~242.50C.

2. Shell side:YD300 heat transfer oil density: 840kg/m3, specific heat 0.63kcal/kg 0C, thermo conductive coefficient 0.106kcal/m.h.oC, viscosity 0.48cst, temperature from 270 oC~267 oC.

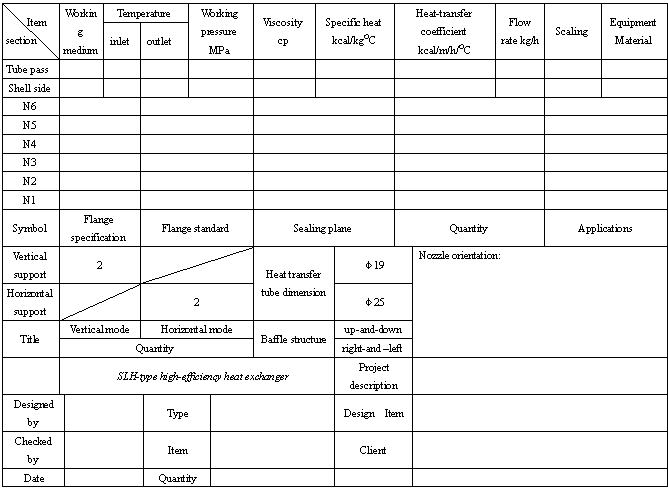

Sheet of technical specifications of SLH-type high-efficiency heat exchanger

Notes:

1. Fill the table according to need;

2. All connection flanges are provided accordingly;

3. Special requirements should be submitted with drawings or character descriptions;

4. In addition to this series, our company can offer design and manufacturing of tandem-tube high-efficiency heat exchanger.